Roof Rack Installation: Step By Step Guide

Whether you’re planning epic road trips with bikes and kayaks or need extra space for family adventures, a properly installed roof rack system transforms your vehicle into the ultimate cargo-carrying machine. The right roof rack system opens up endless possibilities for transporting surfboards, skis, cargo boxes, and outdoor gear that won’t fit inside your car.

This comprehensive step by step guide covers everything you need to know about roof rack install procedures, from selecting the correct tools to performing long-term maintenance. We’ll explore both factory mounting point installations and clip-on systems, ensuring you have the knowledge to tackle this task safely and effectively.

Professional installation services can cost hundreds of dollars, but with attention to detail and the proper process, you can create a secure roof rack setup that delivers years of reliable service. Let’s discover how to add a roof rack to your car and learn the best methods for roof rack install and roof rack assembly.

Essential Tools and Equipment for Roof Rack Installation

Before beginning your roof rack install, gather all necessary tools and equipment to ensure a smooth installation process. Having the right materials ready prevents interruptions and helps maintain focus on proper positioning and secure connections.

Primary Tools Required:

-

Socket wrench set with metric and standard sizes (8mm-19mm most common)

-

Phillips and flathead screwdrivers for various bracket types

-

Measuring tape (at least 6 feet long) for accurate spacing

-

Level tool for proper alignment and parallel positioning

-

Torque wrench for final tightening (10-25 ft-lbs typical range)

-

Protective blankets or towels to prevent scratches and dents

-

Penetrating oil (WD-40 or similar) for stubborn factory bolts

-

Work gloves for better grip and hand protection

Additional Equipment:

Quality tools make the difference between a professional installation and one that leads to problems down the road. The torque wrench is particularly key for achieving manufacturer specifications without overtightening. Many roof rack systems are designed with specific torque requirements that prevent both under-securing and damaging delicate mounting points.

Consider purchasing or borrowing a digital torque wrench if you plan to install multiple rack systems or frequently adjust your setup. This investment pays dividends in preventing costly mistakes that could damage your vehicle’s roof or compromise the rack’s stability.

Pre-Installation Vehicle Preparation

Proper vehicle preparation sets the foundation for a successful roof rack installation. This step determines whether your racks will attach securely and function reliably for years to come.

Cleaning and Inspection Process:

Start by thoroughly washing and drying the vehicle roof to remove all dirt, debris, and road residue. Clean mounting surfaces ensure proper contact between rack components and your car’s attachment points. Pay special attention to areas around factory mounting points where grime commonly accumulates.

Inspect roof mounting points for damage, rust, or missing hardware that could compromise installation safety. Check for small cracks or corrosion around threaded holes, as these indicate potential structural weakness. Any discovered damage should be addressed before proceeding with rack installation.

Preparation Checklist:

-

Remove plastic covers from factory mounting points using manual instructions

-

Check vehicle manual for maximum roof load capacity (typically 100-200 lbs)

-

Verify roof rack compatibility with your specific vehicle year, make, and model

-

Gather all roof rack components and hardware before starting installation

-

Double check that all brackets, bolts, and accessories are included per manufacturer specifications

Weight and Compatibility Verification:

Understanding your vehicle’s load limitations prevents dangerous overloading that could affect handling or cause structural damage. Most passenger vehicles support between 100-200 pounds of roof cargo, but this varies significantly by make and model. The rack system itself typically weighs 20-40 pounds, reducing available cargo capacity accordingly.

Compatibility extends beyond weight limits to include roof design, door frame construction, and integrated vehicle features. Modern cars often include panoramic sunroofs, integrated antennas, or sensor arrays that affect rack mounting options. If you’re wondering, “can I add roof rails to my car?” or “can you add roof rails to a car?”, checking compatibility with your vehicle and the right roof rack system is essential.

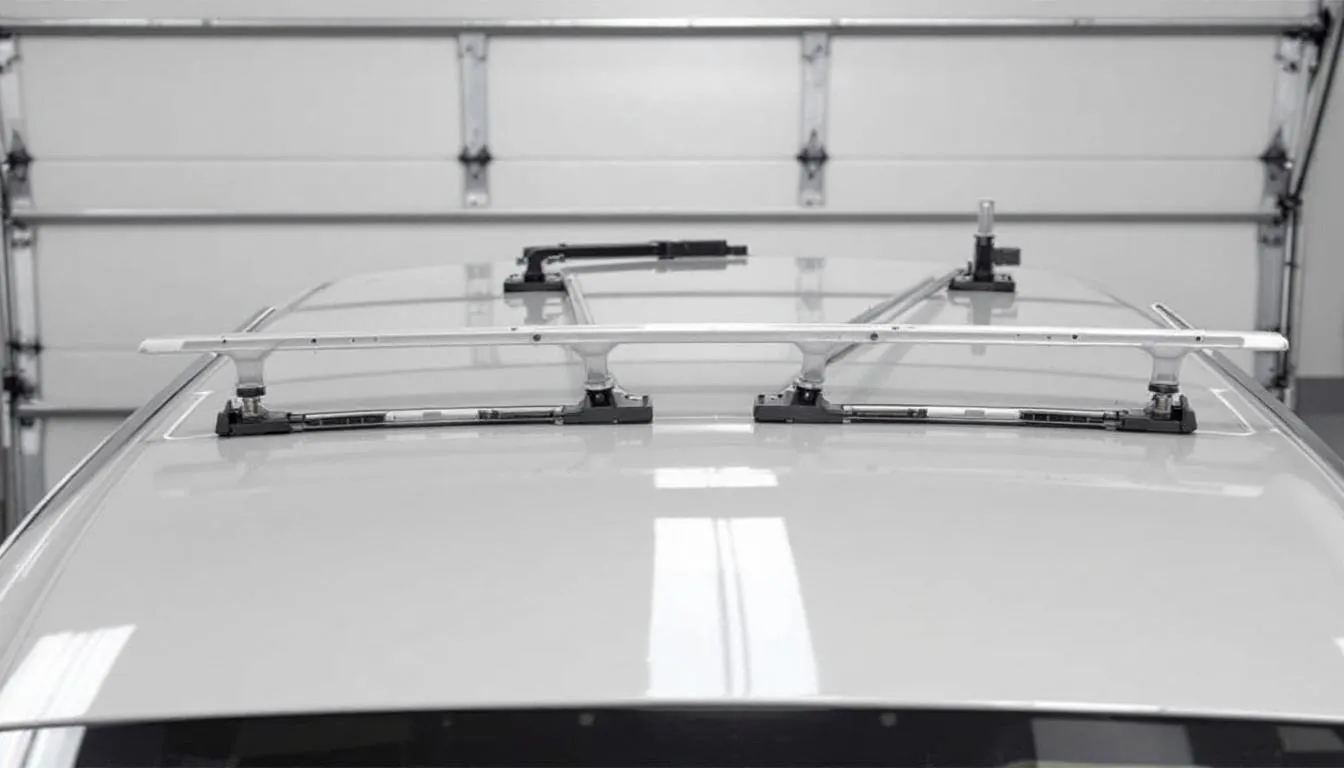

Installing Factory Mounting Point Systems

Factory mounting point installations offer the most secure and reliable connection method for roof racks. These systems utilize engineered attachment points specifically designed to handle roof loads safely.

Locating and Accessing Mounting Points:

Most vehicles equipped for roof racks feature four mounting points positioned symmetrically on the roof. These appear as small plastic covers or plugs that protect threaded inserts when racks aren’t installed. Consult your vehicle manual to confirm mounting point locations, as positioning varies between manufacturers.

Remove plastic covers or plugs using appropriate tools (usually twist counterclockwise). Some covers require gentle prying with a flathead screwdriver, while others simply twist off by hand. Save these covers for reinstallation if you remove the rack system later.

Installation Procedure:

-

Thread mounting bolts through rack feet and position over mounting holes

-

Hand-tighten bolts initially to allow for positioning adjustments

-

Use measuring tape to ensure rack feet are positioned symmetrically

-

Check that all feet sit flush against the roof surface without gaps

-

Apply final torque specification (check manual - typically 15-20 ft-lbs)

Critical Alignment Steps:

Proper alignment prevents uneven stress distribution that could damage mounting points or create instability. Measure diagonally from corner to corner to verify rectangular alignment. The diagonal measurements should be identical within 1/4 inch.

This systematic approach ensures your rack system distributes loads evenly across all four mounting points, maximizing safety and durability. Take time during this step, as realigning after final tightening requires loosening all connections.

If you’re looking for “roof rack how to install” or “how do you install a roof rack,” this method using factory fixed points is the most secure and recommended.

Installing Clip-On Roof Rack Systems

Clip-on systems provide rack mounting capability for vehicles without factory attachment points. These universal systems clamp to door frames and roof edges, creating secure anchor points through mechanical tension.

Positioning and Adjustment:

Position door frame clips at designated points along the roof edge, following manufacturer spacing requirements. The exact position depends on your vehicle’s door frame design and the rack system’s specifications. Most clip systems include vehicle-specific guides that simplify positioning.

Ensure rubber padding makes full contact with door frame surfaces to prevent paint damage and provide secure grip. Gaps between padding and vehicle surfaces reduce holding power and increase the risk of scratches or dents during use.

Installation Steps:

-

Adjust clip tension gradually to avoid overtightening and damage

-

Verify even pressure distribution across all clip contact points

-

Check that clips sit flush without gaps between padding and vehicle

-

Test clip security by gently attempting to move rack laterally

-

Mark final positions for easy reinstallation after removal

Tension and Security Verification:

Proper clip tension balances holding power with paint protection. Insufficient tension allows movement that could damage your vehicle’s finish, while excessive tension may leave permanent marks on door frames or roof edges.

Test installation security by applying moderate sideways pressure to each attachment point. Well-installed clips should show no movement or shifting when reasonable force is applied. Any detected movement requires readjustment before proceeding to crossbar installation.

If you want to “install roof rails on car” or “install roof rails on bare roof,” clip-on systems are a practical solution for vehicles without fixed points.

Crossbar Installation and Positioning

Crossbar positioning directly affects load stability, weight distribution, and aerodynamic performance. Proper spacing and alignment create a stable platform for carrying diverse cargo types safely.

Positioning Guidelines:

Mount crossbars to installed feet according to manufacturer specifications, paying careful attention to front-to-rear spacing. Position the front crossbar 24-36 inches from the vehicle’s front edge to avoid interference with windshield airflow and reduce wind noise.

Space the rear crossbar 24-36 inches behind the front bar for optimal load distribution. This spacing accommodates most cargo types while maintaining stability. Longer items like kayaks or lumber may require adjusted spacing, but maintain at least 24 inches between bars.

Alignment Procedures:

-

Use level tool to ensure crossbars are perpendicular to vehicle centerline

-

Measure diagonal distances to confirm rectangular rack alignment

-

Adjust crossbar spacing based on cargo length requirements

-

Verify parallel alignment by measuring multiple points along each bar

-

Double check that crossbars don’t interfere with sunroof operation

Critical Measurements:

Diagonal measurements from front left to rear right and front right to rear left must be identical for proper rectangular alignment. Differences greater than 1/4 inch indicate misalignment that could cause cargo instability or uneven wear on mounting hardware.

Use the measuring tape to verify consistent spacing between crossbars at multiple points. Parallel bars ensure even weight distribution and prevent cargo from sliding during transport.

Load Distribution Guidelines

Understanding proper load distribution maximizes safety and prevents damage to your vehicle or cargo. Even weight placement reduces stress on individual mounting points and maintains vehicle handling characteristics.

Weight Distribution Principles:

-

Distribute weight evenly between front and rear crossbars for stability

-

Keep heaviest items centered between crossbars to minimize stress concentration

-

Maintain 60/40 weight distribution (60% on rear crossbar) for optimal handling

-

Avoid exceeding single crossbar weight limits (typically 50-75 lbs each)

-

Position irregular loads to maintain vehicle balance and aerodynamic efficiency

Load Securing Methods:

Secure all cargo with appropriate tie-downs rated for the load weight. Ratchet straps offer superior holding power compared to bungee cords for heavy items. Cross-strap technique, where straps form an “X” pattern over the load, provides maximum security for irregularly shaped cargo.

Regular load checks during long trips ensure cargo remains secure. Stop every 50-100 miles to verify tie-down tension and cargo positioning, especially during the first few trips with a new rack system.

If you are learning “how to install roof bars” or “fitting roof bars,” proper crossbar installation is key to a safe and versatile roof rack assembly.

Final Tightening and Safety Checks

The final tightening phase transforms your assembled rack system into a secure cargo platform ready for years of reliable service. This critical step requires systematic approach and attention to manufacturer specifications.

Tightening Sequence:

Tighten all bolts gradually in a cross pattern to ensure even pressure distribution across mounting surfaces. This technique prevents warping or stress concentration that could damage mounting points or create instability.

Apply manufacturer-specified torque values using your torque wrench for consistent, reliable connections. Under-tightening allows movement that could damage threads or mounting surfaces, while overtightening risks stripping threads or cracking mounting points.

Comprehensive Safety Verification:

-

Double-check all connections are secure without overtightening

-

Verify no hardware interference with sunroof, antenna, or other roof components

-

Test rack stability by applying moderate downward pressure at various points

-

Check that all bolts turn smoothly without binding or cross-threading

-

Document installation date and torque specifications for future reference

Integration Checks:

Modern vehicles include numerous roof-mounted systems that could interfere with rack operation. Verify that your installation doesn’t block GPS antennas, satellite radio receivers, or emergency communication equipment. Test sunroof operation through its full range of motion to ensure clearance.

Antenna interference typically manifests as reduced radio reception quality. If you notice degraded reception after installation, check antenna proximity to rack components and adjust positioning if possible.

Documentation and Record Keeping:

Maintain installation records including torque specifications, installation date, and any adjustments made during setup. This information proves valuable during maintenance intervals and helps troubleshoot any issues that develop over time.

Photograph your completed installation from multiple angles. These images serve as reference points for proper positioning and help identify changes that might indicate loosening hardware or mounting point problems.

If you want to “mount roof rack” or “attach roof rack to car,” these final tightening and safety checks are essential steps in the roof rack install process.

Installation Testing and Break-in Period

A systematic break-in period allows rack components to settle properly while identifying any installation issues before they become serious problems. This gradual approach maximizes safety and system longevity.

Initial Testing Protocol:

Load your rack system with lightweight cargo for the initial test drive (10-15 lbs maximum). This minimal load allows you to evaluate installation stability without risking damage from heavy cargo if problems exist.

Drive at moderate speeds (25-35 mph) for the first 10 miles, paying attention to any unusual noises, vibrations, or handling changes. Stop after this initial test drive to inspect all connections and verify that nothing has shifted or loosened.

Progressive Load Testing:

-

Start with lightweight items for first week of use

-

Gradually increase load weight over first 100 miles of driving

-

Perform monthly tightness checks for first three months after installation

-

Monitor for any signs of stress or wear at mounting points

-

Document any adjustments needed during break-in period

Audio and Vibration Assessment:

Listen for unusual noises that could indicate loose hardware or improper installation. Common warning sounds include rattling (loose bolts), whistling (aerodynamic issues), or clicking (inadequate thread engagement).

Vibration transmitted through the vehicle structure often indicates uneven loading or misaligned components. Address any detected vibrations immediately, as they typically worsen over time and may damage mounting systems.

Performance Monitoring:

Track fuel economy changes after rack installation to establish baseline consumption with your system. Most roof racks reduce fuel efficiency by 2-15% depending on design and loading. Dramatic efficiency losses may indicate aerodynamic problems requiring adjustment.

Monitor vehicle handling characteristics, particularly during crosswinds or highway driving. Properly installed racks should have minimal impact on normal driving dynamics.

Common Installation Mistakes to Avoid

Learning from common installation errors prevents costly damage and ensures safe, reliable rack operation. These mistakes represent the most frequent issues encountered by both DIY installers and professional technicians.

Critical Error Categories:

Hardware and Torque Mistakes:

-

Overtightening bolts leading to thread damage or mounting point cracks

-

Using incorrect hardware that doesn’t match manufacturer specifications

-

Mixing bolts from different rack systems or installation kits

-

Failing to apply anti-seize compound on steel bolts in aluminum receivers

Alignment and Positioning Errors:

-

Improper crossbar spacing causing cargo instability during transport

-

Misaligned mounting feet creating uneven stress distribution

-

Inadequate clearance checks with sunroof, antenna, or sensor systems

-

Ignoring vehicle-specific positioning requirements detailed in instructions

Preparation and Maintenance Oversights:

Installing racks without thoroughly cleaning mounting surfaces creates poor connections that may loosen over time. Dirt, wax, or debris prevents proper contact between components and reduces holding power.

Failing to use protective padding on clip-on systems frequently results in paint damage that’s expensive to repair. Quality padding costs far less than professional paint correction services.

Load and Safety Violations:

Ignoring manufacturer weight limits ranks among the most dangerous installation mistakes. Exceeding capacity limits can cause catastrophic failure during transport, potentially causing accidents or serious property damage.

Not testing installation before loading heavy cargo creates unnecessary risk. Always verify system security with light loads before progressing to heavier items.

Prevention Strategies:

Create a detailed checklist covering all installation steps, including torque specifications and alignment measurements. Check items off systematically to avoid skipping critical procedures.

Take photographs during installation to document proper component positioning and hardware orientation. These images prove invaluable if disassembly becomes necessary.

Maintenance and Long-term Care

Regular maintenance preserves roof rack performance and extends system lifespan significantly. A systematic maintenance approach prevents small problems from developing into expensive repairs or safety hazards.

Monthly Inspection Routine:

Inspect rack tightness monthly during periods of regular use, focusing on connections that experience the most stress. Thermal cycling from temperature changes and vibration from road travel gradually loosen hardware over time.

Check mounting points for any signs of stress, corrosion, or damage. Early detection of problems allows for correction before they compromise safety or require expensive repairs.

Quarterly Maintenance Tasks:

-

Clean mounting points and hardware every three months using appropriate solvents

-

Apply anti-seize compound to bolts during maintenance intervals

-

Replace worn rubber seals and padding as needed to maintain protection

-

Lubricate adjustment mechanisms on removable or adjustable systems

-

Inspect crossbars for stress cracks or impact damage

Seasonal Care Considerations:

Remove roof rack systems during automatic car washes to prevent damage from brushes and high-pressure spray. Hand washing allows better control and prevents unnecessary wear on rack components and vehicle finish.

Store removable components in a dry location during off-seasons when racks aren’t needed. Proper storage prevents corrosion and extends component lifespan significantly.

Long-term Durability Factors:

Quality maintenance preserves the investment in your roof rack system while ensuring continued safe operation. Well-maintained racks often provide decades of reliable service, making the initial installation effort worthwhile.

Document maintenance activities including dates, procedures performed, and any components replaced. This record helps establish maintenance intervals and provides valuable information for warranty claims if needed.

Professional Service Considerations:

Consider professional inspection annually for heavily used rack systems or after any impact damage. Professional technicians can identify subtle problems that might escape notice during routine owner inspections.

Some manufacturers offer extended warranties that require professional maintenance intervals. Verify warranty requirements to avoid inadvertently voiding coverage through improper maintenance procedures.

Roof Rack Accessories: Enhancing Your Setup

To maximize the versatility of your roof rack system, consider adding roof rack accessories that are compatible with your setup. Accessories such as bike racks, cargo boxes, ski and snowboard carriers, and awnings can be purchased separately and tailored to your specific needs.

Popular Roof Rack Accessories Include:

-

Bike racks for secure transportation of bicycles

-

Cargo boxes to increase storage capacity and protect gear from weather

-

Ski and snowboard carriers for winter sports equipment

-

Awnings that provide shade and shelter during outdoor activities

When selecting accessories, ensure they are compatible with your roof rack system and vehicle. Using the right accessories enhances the functionality and convenience of your roof rack setup, allowing you to press forward with your adventures without worry.

Conclusion

Successfully completing a roof rack install transforms your vehicle into a versatile cargo-carrying platform ready for countless adventures. This comprehensive guide provides the knowledge and step-by-step procedures needed to create a safe, secure installation that will serve you reliably for years to come.

Remember that patience and attention to detail during installation prevent problems that could compromise safety or require expensive corrections later. Take time to understand your specific vehicle’s requirements, follow manufacturer instructions precisely, and never compromise on safety by exceeding weight limits or skipping critical steps.

Whether you’re planning family road trips, hauling bikes for weekend adventures, or need extra space for work equipment, a properly installed roof rack system opens up new possibilities for using your vehicle. The versatility and durability of modern roof rack systems and their accessories make them excellent investments that enhance both recreational and practical vehicle use.